Lithium batteries are widely used in many electronic products (laptops, mobile phones, mobile power supplies, shared bicycles, etc.). Its advantages are that it can be cycled and has a long service life and volume. It is also small and most importantly does not pollute the environment. The small size, high sensitivity thermistor plays a very important role in lithium batteries. It specializes in temperature detection and control, because it will become smaller as the temperature rises, which can prevent the battery from overheating, resulting in Dangerous.

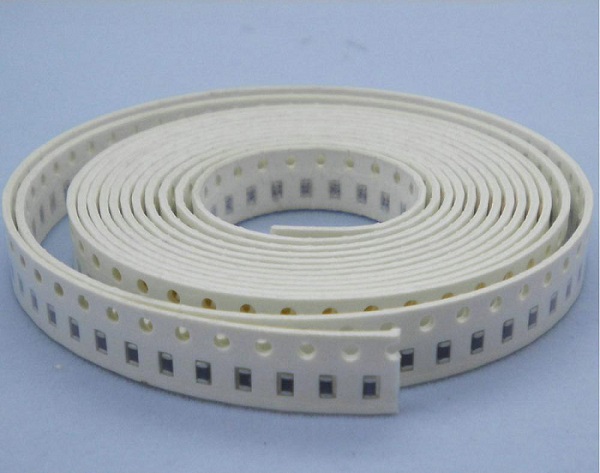

At present, the traditional and commonly used NTC thermistor is manual plug-in type, only You need to manually solder and then stick the thermistor contacts on the battery core, and finally fix it with thermal conductive adhesive. Today I will introduce a chip NTC thermistor. This thermistor will have more benefits when applied to lithium batteries.

SMD NTC thermistors have a volume and weight of only about 1/10 of the latter compared to plug-in thermistors and are used in The volume of electronic products is reduced by at least 40% ~ 60%, and the weight is reduced by 60% ~ 80%; it also reduces electromagnetic and radio frequency interference, so that it is easy to achieve automation and improve production efficiency. Thereby reducing costs by 30% to 50%, saving materials, energy, equipment, manpower, time, etc.

The circuit structure of the lithium battery protection board of the chip NTC thermistor includes There are many aspects: charging circuit, discharging circuit, control chip, multiple resistance-capacitance components, multiple MOSFET switching devices and NTC thermistors, diodes (four), zener diodes (two), fuses and potentiometers.

The advantages of SMD NTC thermistor:

High density, small size, Light weight;

Good moisture resistance, high stability and high reliability;

Anti Strong vibration capability, low defect rate of solder joints, and good high frequency characteristics.

How does SMD NTC thermistor work in it?

Through multiple resistance-capacitance elements (including thirty resistors and twenty-three capacitors) to detect the battery voltage and loop current, and through multiple MOSFET switching devices (There are four) to control the on and off of the charging circuit and the discharging circuit. The thermistor is connected in series between multiple resistance components and the battery.

The use of SMD NTC thermistors has the following advantages: Lithium battery The addition of a new type of chip-type NTC thermistor greatly shortens the processing time of production, and can also avoid unnecessary troubles, such as short circuits, breaks, and shifts; these can cause large deviations in temperature measurement, and even It can also cause security incidents.

The lithium battery with the new thermistor is more effective in detecting temperature, etc. The plug-in type should be more reliable, effective, smaller, more convenient and more practical.